Sump

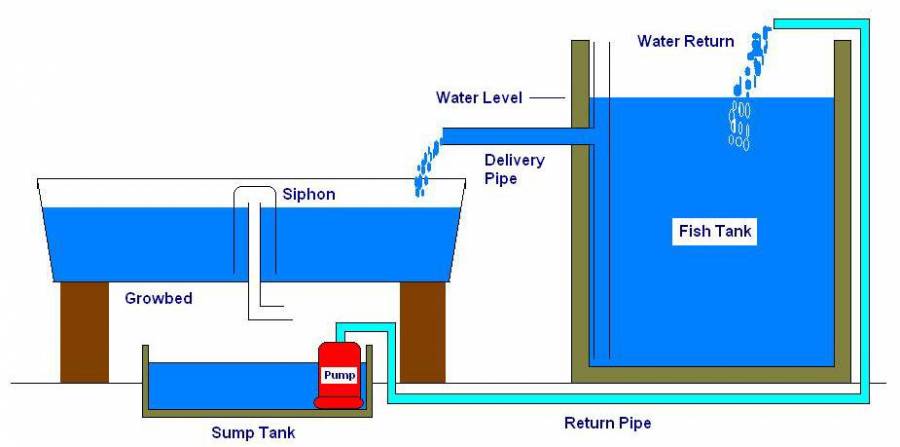

Water flows by gravity from gravel, sand and raft hydroponic subsystems to a sump, which is the lowest point in the system. The sump contains a pump or pump inlet that returns the treated culture water to the rearing tanks. If NFT troughs or perlite trays are located above the rearing tanks, the sump would be positioned in front of them so that water could be pumped up to the hydroponic component for gravity return to the rearing tanks.

Water flows by gravity from gravel, sand and raft hydroponic subsystems to a sump, which is the lowest point in the system. The sump contains a pump or pump inlet that returns the treated culture water to the rearing tanks. If NFT troughs or perlite trays are located above the rearing tanks, the sump would be positioned in front of them so that water could be pumped up to the hydroponic component for gravity return to the rearing tanks.

- There should be only one pump to circulate water in an aquaponic system.

- The sump should be the only tank in the system where the water level decreases because of overall water loss from evaporation, transpiration, sludge removal and splashing.

An electrical or mechanical valve is used to automatically add replacement water from a storage reservoir or well.

- Municipal water should not be used unless it is de-chlorinated.

- Surface water should not be used because it may contain disease organisms.

- A water meter should be used to record additions. Unusually high-water consumption indicates a leak.

The sump is a good location for the addition of base to the system. Soluble base such as potassium hydroxide causes high and toxic pH levels in the sump.

However, as water is pumped into the rearing tank, it is diluted and pH decreases to acceptable levels.

The UVI system has a separate base addition tank located next to the sump. As water is pumped from the sump to the fish-rearing tanks, a small pipe, tapped into the main water distribution line, delivers a small flow of water to the base addi- tion tank, which is well aerated with one large air diffuser. When base is added to this tank and dissolves, the resulting high pH water slowly flows by gravity into the sump, where it is rapidly diluted and pumped to fish- rearing tanks. This system prevents a rapid pH increase in the fish-rearing tank.

Construction materials

Many materials can be used to construct aquaponic systems components. Budget limitations often lead to the selection of inexpensive and questionable materials such as vinyl-lined, steel-walled swimming pools. Plasticisers used in vinyl manufacture are toxic to fish, so these liners must be washed thoroughly or aged with water for several weeks before fish can be added safely to a tank of clean water. After a few growing periods, vinyl liners shrink upon drying, become brittle and crack, while the steel walls gradually rust. Nylon-reinforced, neoprene rubber liners are not recommended either. Tilapia eat holes in rubber liners at the folds as they graze on microorganisms. Moreover, neoprene rubber liners are not impervious to chemicals. If herbicides and soil sterilants are applied under or near rubber liners, these chemicals can diffuse into culture water, accumulate in fish tissue and kill hydroponic vegetables.

Many materials can be used to construct aquaponic systems components. Budget limitations often lead to the selection of inexpensive and questionable materials such as vinyl-lined, steel-walled swimming pools. Plasticisers used in vinyl manufacture are toxic to fish, so these liners must be washed thoroughly or aged with water for several weeks before fish can be added safely to a tank of clean water. After a few growing periods, vinyl liners shrink upon drying, become brittle and crack, while the steel walls gradually rust. Nylon-reinforced, neoprene rubber liners are not recommended either. Tilapia eat holes in rubber liners at the folds as they graze on microorganisms. Moreover, neoprene rubber liners are not impervious to chemicals. If herbicides and soil sterilants are applied under or near rubber liners, these chemicals can diffuse into culture water, accumulate in fish tissue and kill hydroponic vegetables.

Fiberglass is the best construction material for rearing tanks, sumps and filter tanks. Fiberglass tanks are sturdy, durable, non-toxic, movable and easy to plumb. Polyethylene tanks are also very popular for fish rearing and gravel hydroponics because of their low cost. NFT troughs made from extruded polyethylene are specifically designed to prevent the puddling and water stagnation that lead to root death and are preferable to makeshift structures such as PVC pipes. Plastic troughs are commercially available for floating hydroponic subsystems, but they are expensive. A good alternative is the 20-mil polyethylene liners that are placed inside concrete block or poured-concrete side walls. They are easy to install, relatively inexpensive and durable, with an expected life of 12 to 15 years. A soil floor covered with fine sand will prevent sharp objects from puncturing the liners. Lined hydroponic tanks can be constructed to very large sizes, hundreds of feet long and up to 30 feet wide.